Technology-driven Company that

supports Research & Development,

Accepts the Challenge of

Worldwide Technology.

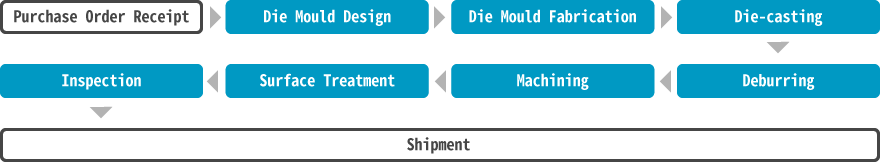

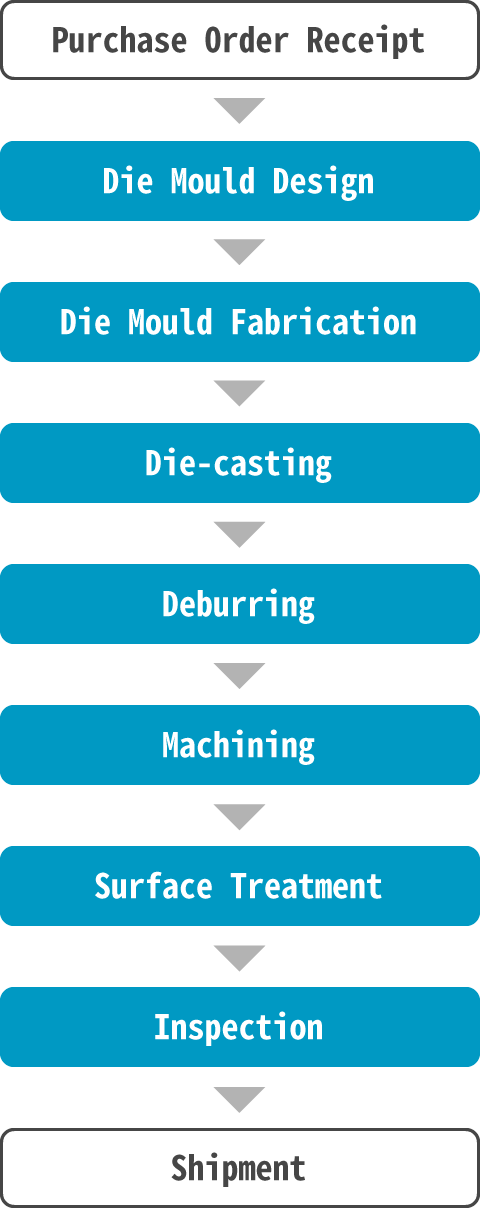

Core business processes: Die mould design of Aluminum products, die-casting, deburring, and machining.

We are committed to promote technological advancement from product design to product realization, upholding our Corporate Social Responsibility (CSR) and Environmental Responsibility.

Purchase Order Receipt to Shipment

Integrated manufacturing satisfies customer order requirement

with guaranteed high quality products in short delivery lead time.

What is Die-Casting?

Die-casting is a manufacturing process in which a high precision mould is installed into a die-casting machine, and molten metal (mainly Aluminum, Zinc, Magnesium) is injected into the mould at high pressure and high speed. Compared to Iron metals, Aluminum is lighter and can produce geometrically complex metal parts. Aluminum is used in vehicles such as automobiles and motorcycles, as well as in electrical and information equipment. Aluminum die-casting is friendly to the environment since the low density of alloys can reduce wastes and scrap materials are recyclable.

Die-Casting

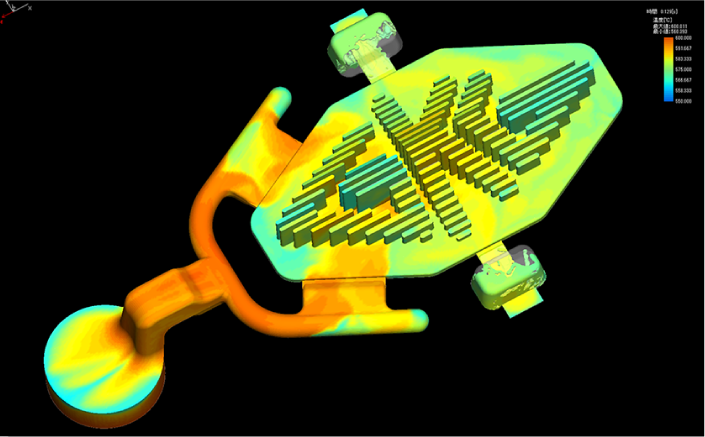

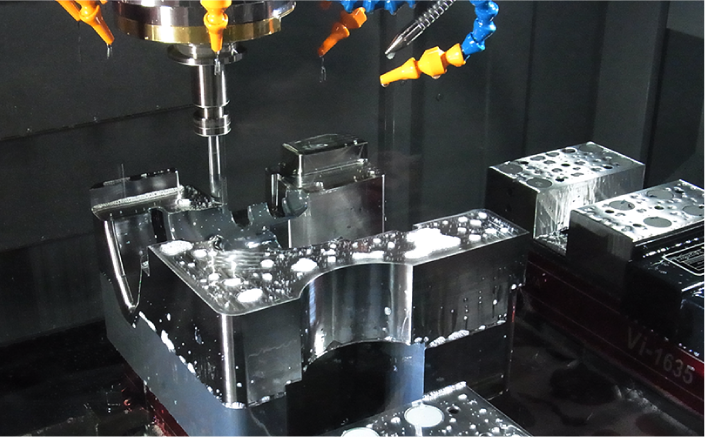

Machining

Measurement

Provides High Quality Products

with Superior Design and Analysis

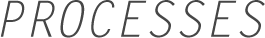

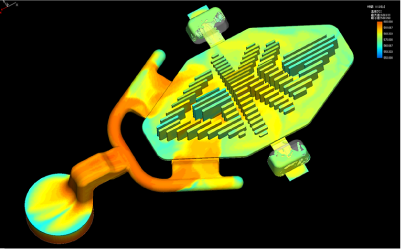

Design and Analysis

Once product drawing is received from customer, it will be converted into drawing for die-casting. Then, die mould design starts. Simulation of molten metal flow analysis will be done. Mould fabrication starts.

Holding Facilities

| Diecasting Process | |||

|---|---|---|---|

| Aluminum Diecasting Machine - 350 tons | 7 units | Trimming Press Machine | 5 units |

| Aluminum Diecasting Machine - 250 tons | 5 units | Shotblasting Machine - Barrel Type | 1 unit |

| Melting and Holding Furnace - 150 kg/hr | 6 units | Shotblasting Machine - Hanger Type | 4 units |

| Melting and Holding Furnace - 200 kg/hr | 6 units | ||

| Machining Process | |||

| CNC Lathe Machine | 11 units | Reaming Machine | 5 units |

| CNC Milling and Tapping Machine | 45 units | Vacuum Impregnation Machine | 1 unit |

| Turret Center | 6 units | Airleak Tester | 3 units |

| Design and Analysis Engineering | |||

| 2D CAD | 2 licenses | 3D CAD - Solid Works | 3 licenses |

| Measuring Equipment | |||

| Coordinate Measuring Machine | 4 units | Surface Tester Machine | 1 unit |

| Coordinate Measuring Machine (Portable) | 1 unit | Hardness Tester Machine | 1 unit |

| Contour Measuring Machine | 1 unit | Universal Testing Machine | 1 unit |

| Roundness Tester Machine | 1 unit | Optical Emission Spectrometer | 1 unit |

| Diecasting Process | |

|---|---|

| Aluminum Diecasting Machine - 350 tons | 7 units |

| Aluminum Diecasting Machine - 250 tons | 5 units |

| Melting and Holding Furnace - 150 kg/hr | 6 units |

| Melting and Holding Furnace - 200 kg/hr | 6 units |

| Trimming Press Machine | 5 units |

| Shotblasting Machine - Barrel Type | 1 unit |

| Shotblasting Machine - Hanger Type | 4 units |

| Machining Process | |

| CNC Lathe Machine | 11 units |

| CNC Milling and Tapping Machine | 45 units |

| Turret Center | 6 units |

| Reaming Machine | 5 units |

| Vacuum Impregnation Machine | 1 unit |

| Airleak Tester | 3 units |

| Design and Analysis Engineering | |

| 2D CAD | 2 licenses |

| 3D CAD - Solid Works | 3 licenses |

| Measuring Equipment | |

| Coordinate Measuring Machine | 4 units |

| Coordinate Measuring Machine (Portable) | 1 unit |

| Contour Measuring Machine | 1 unit |

| Roundness Tester Machine | 1 unit |

| Surface Tester Machine | 1 unit |

| Hardness Tester Machine | 1 unit |

| Universal Testing Machine | 1 unit |

| Optical Emission Spectrometer | 1 unit |